Image source: https://image.slidesharecdn.com/chapter13heattreatmentofsteels-131211101232-phpapp02/95/heat-treatment-of-steels-8-638.jpg?cb=1386756825

Temperature is the much critical factor that controls the strength of the thermal oxide silicon wafers, and this be saved in mind when environment temperature ramping and furnace pull/push prerequisites. The strength of the wafer decreases kind of when the temperature is greater from 700C to 800C. If wafers are pulled or driven into a furnace with the tube set at 800C, the slip creates issue and can smash it. Therefore, the strength of the wafer is inversely proportional to the augment in temperature. It is a wishes to-may still use lessen ramping costs for better temperature levels to sidestep wafer slip all over the global furnace temperature ramping.

After years of reviews in fabrication of ICs (on silicon wafers), engineers determined that furnace slip has continually created a issue. The engineers have continually confronted disorders in expanding the speed of furnace, temperature ramps and push-pull to maximise the furnace output. However, at an analogous it additionally is vitally important to restrain the speed of temperature ramps and push-pull to sidestep wafer smash. Whenever a present day IC technology produces prime fitted-in components stress, the steadiness shifts. This is considering furnace recipes which had earlier created slip-free silicon wafers grew to be recipes which created big furnace slip.

In the thermal cycling method, the tension which takes place on oxide is used on the trench of sidewalls. The thermal stress created as a consequence of temperature non-uniformities in the wafer generate slip dislocations and shift those dislocations into the leakage refined quarter of the components. Now days IC gadgets with STI buildings will be fabricated smoothly by moderating similarly the furnace stress and the fitted-in IC components stress.

The silicon wafers are sturdy at room temperature, but they notice yourself weaker because the temperature is greater. The furnace manufacturing steps are a wishes to-have for the processing of ICs (integrated circuits). During this method a non-uniform extreme temperature produces a non-uniform enlargement within of the wafer. Therefore, a consequential thermal stress can end in restricted or intensive furnace slip.

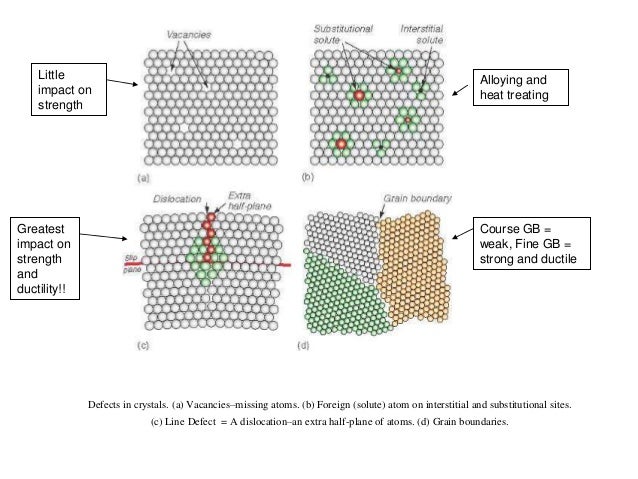

The better the density of dislocations in a thermal oxide silicon wafer, the weaker the wafer. It takes a sizable stress to create a dislocation, but basically a small stress can end in an existing dislocation to multiply or pass.

The better the interstitial oxygen concentration, the stronger the wafer. Dissolved or interstitial oxygen atoms attach themselves with dislocations and forestall them from multiplying.

The better the quantity of precipitated oxygen, the weaker the wafer. Increasing oxygen precipitates fritter away the interstitial oxygen and blow out the new dislocations.

The better the concentration of dopant atoms, the stronger the silicon wafers. The damaged fields circular atoms, which are larger or smaller than the silicon atoms, impede the movement of dislocations.

Integrated circuit movies can follow stress on the underlying silicon wafers and make slip superior. Trench and other IC buildings, apart from mechanical smash considerations, can visit pot the wafer by displaying as stress concentrators.

It obstructs the formation of silicon crystalline architecture and certainly decomposes the electrical and physical sides of the wafer. The dislocations which might be shaped by slip can end in gate oxide integrity collapse, extreme junction leakage, and untimely breakdown. The physical deformation can end in wafer breakage, sample misalignment, chucking disorders and awareness instability.

A non-uniform temperature is produced in the silicon wafer all over the global temperature furnace push. This motives a bright beaming calories from the kiln tube to warm temperature up the wafer edge prior than the wafer middle. This additionally can end in slip across the silicon wafer edge and the deformation of the silicon wafer. During temperature ramp-down and furnace pull, the wafer cools earlier on the rims than in the center.This end in temperature non-uniformity on the wafer middle and motives the wafer to bend.